From May 28 to 31, 2025, Istanbul Exhibition Center in Turkey welcomed a grand carnival in the industrial field - Turkey International Industrial Fair. The exhibition is jointly organized by Deutsche Messe AG and Hannover Fairs (Turkey) Co., Ltd., and has become a focus event in the global industrial community with its annual frequency.

The exhibition was unprecedented in scale, with 750 companies from 19 countries gathered on an exhibition area of 60,000 square meters. These companies, like shining stars, rushed to Istanbul with the cutting-edge industrial achievements of their respective countries and companies, pushing the internationalization of the exhibition to a new height. The enthusiasm of professional visitors was also high. 41,554 professionals from 90 countries crossed mountains and seas to gather here, eager to explore the industry's cutting-edge technologies and innovative products in this exhibition.

The five carefully crafted industrial theme exhibitions and special exhibition areas of the exhibition have their own merits. Welding and cutting technology; energy, electrical and electronic technology; integrated automation and fluid power transmission; sheet metal processing, metal cutting and forming technology; logistics, supply chain management and internal logistics solutions. The successful holding of this exhibition not only built an efficient communication and cooperation platform for global industrial enterprises, but also promoted the dissemination and application of cutting-edge technologies in various industries, injecting strong impetus into future industrial development. In this global industrial feast, Shenzhen Aiostar Electronics Co., Ltd. (referred to as "Aiostar") is particularly eye-catching. As a company specializing in the production of industrial equipment, Aiostar brought its core products, industrial industrial computers, industrial motherboards, industrial tablets, etc. to the heavy appearance.

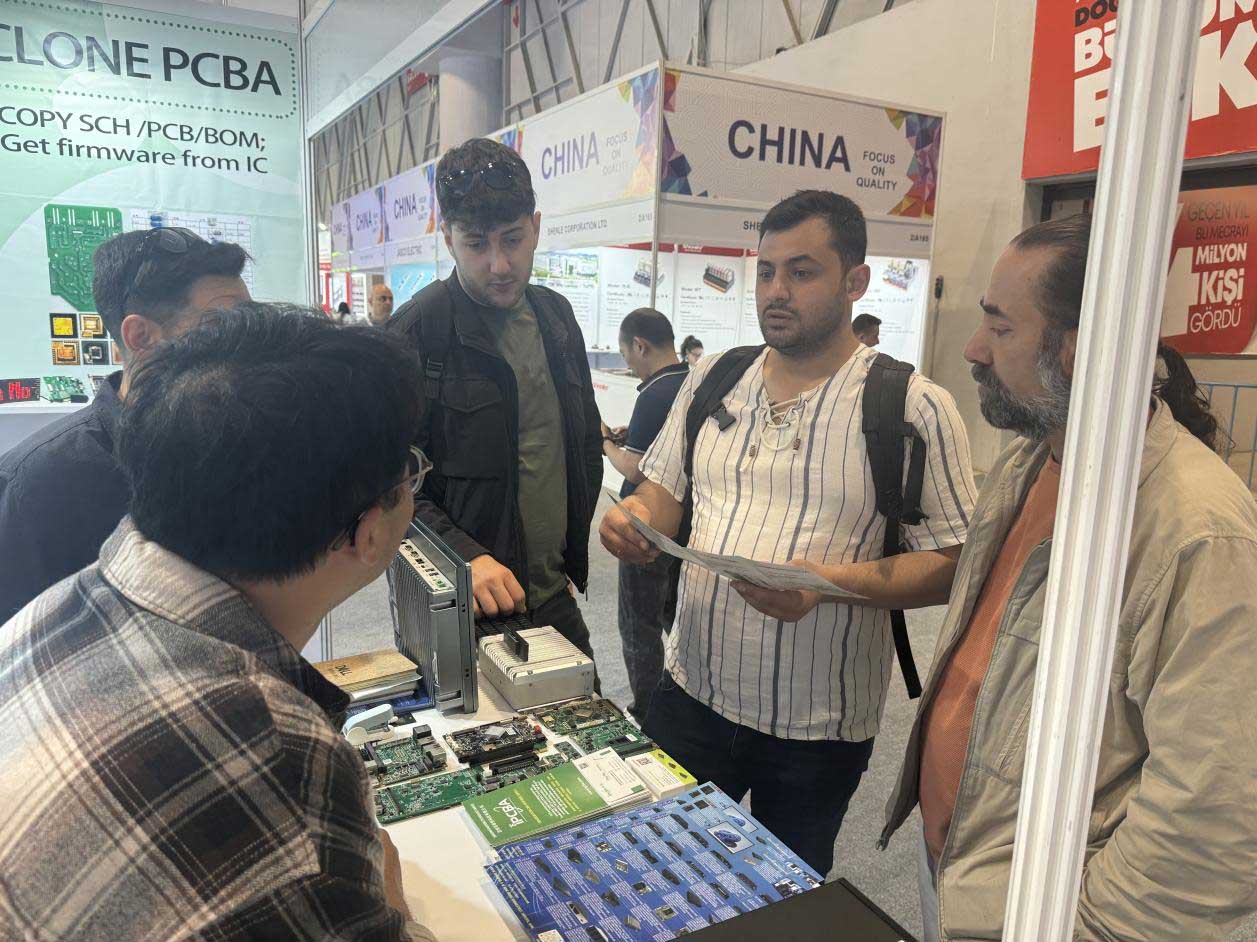

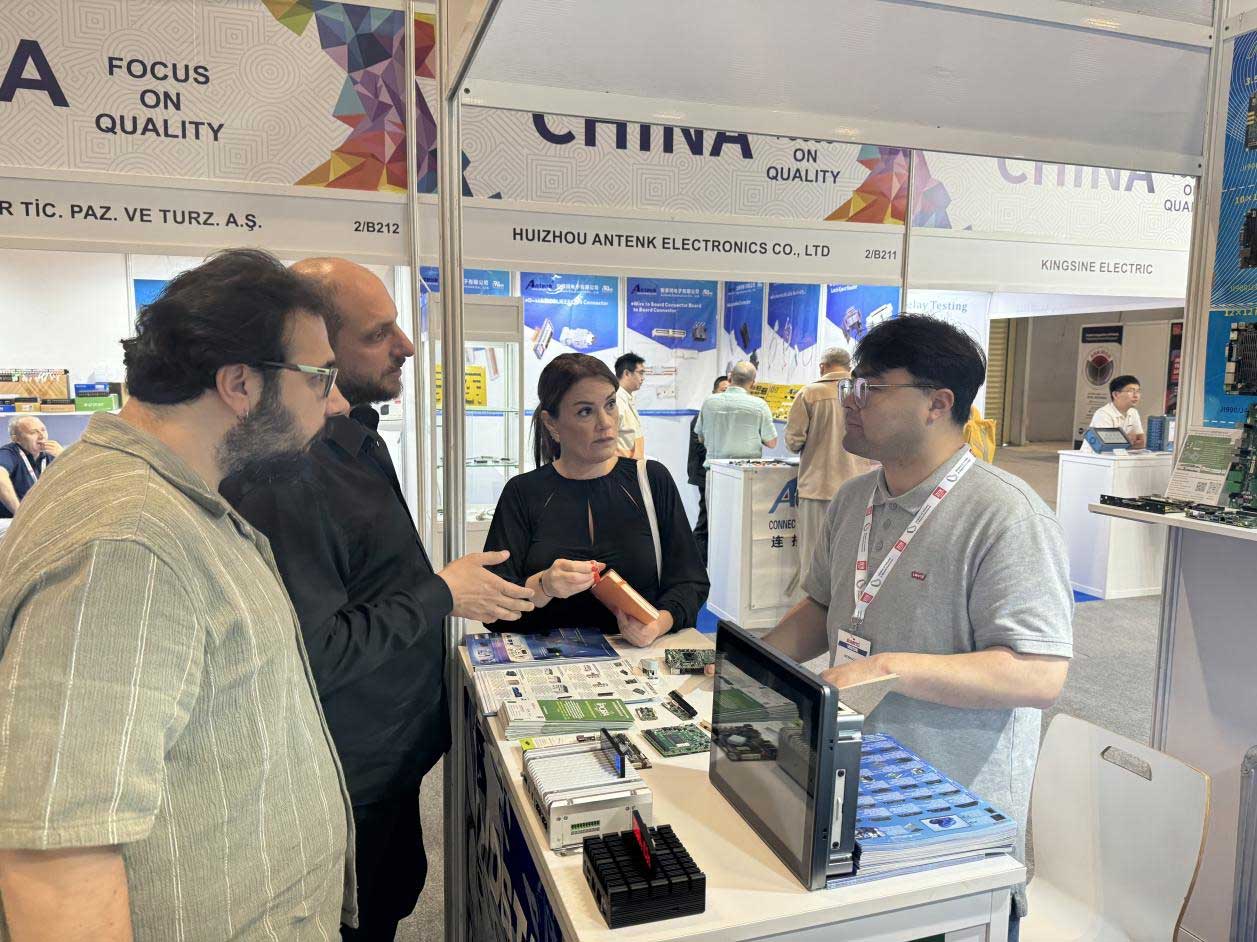

In the special display area of digital factories integrating industrial automation production, AI robots and control terminals, Aiostar's booth was crowded with people and became the focus of the whole venue. Every visitor who stopped by had a strong interest in cutting-edge industrial technology in their eyes. They shuttled between various exhibits and felt the strong pulse of China's industrial equipment manufacturing. Entering the booth, Aiostar's industrial computer series is like a strong "heart", injecting a steady stream of power into the field of industrial automation, especially showing excellent performance in AI robot control and industrial automatic production lines. Its industrial computer family lineup is huge and each has its own strengths. 4U industrial computers, wall-mounted industrial computers and embedded fanless industrial computers, each of which shines in their respective fields. With its standardized rack structure and powerful expansion capabilities, the 4U industrial computer occupies an important position in the field of industrial automation and edge computing. It has a spacious internal space that can easily accommodate multiple PCI/PCIe expansion cards, which makes it an ideal choice for building complex control systems or data acquisition platforms. At the same time, the multi-fan active cooling system is like a "breathing system" for it, ensuring continuous and stable operation under high-load environments. In industrial automatic production lines, it is often deployed in data centers, industrial control rooms or equipment rooms, undertaking heavy tasks such as video analysis, machine vision, and manufacturing execution systems (MES). It is the core node of medium and large industrial projects and provides solid support for the efficient operation of production lines. In terms of AI robot control, its powerful computing power can accurately process the complex instructions of the robot, allowing the robot to operate flexibly on the production line. The wall-mounted industrial computer is characterized by compact structure and convenient installation, and it is very useful in industrial sites with limited space. It supports a variety of chipsets and processor platforms, such as Intel B75, B85, H110, Q170, B560, Q670, H610, etc. The interface configuration is flexible and diverse, and the design of multiple serial ports, USB and network ports facilitates the connection of various peripherals or control modules, playing an important role in the central control link of industrial automatic production lines. The solid metal shell gives it good dust and shock resistance, and it can be directly mounted on the wall or in the control cabinet. Whether it is the precise control of equipment in the power automation scene or the collaborative operation with AI robots in the smart manufacturing workshop, it can complete the task excellently, and is an indispensable "all-rounder" in the industrial field.

Embedded fanless industrial computers interpret stability and quietness to the extreme. The pure passive heat dissipation design avoids dust accumulation and mechanical failure caused by fan operation, providing reliable guarantee for the continuous operation of AI robot control and industrial automatic production lines. It is compact and can be easily embedded in self-service equipment, vehicle control systems, etc., and can stick to its post in harsh environments. The selection of low-power platforms and support for multiple industrial communication protocols make it easy to operate in smart retail, rail transit and other fields, especially in industrial automatic production lines and AI robot control scenarios that require extremely quiet operation and reliability. It has become an ideal choice. These industrial computers can not only easily support Intel notebook operations, but also perform well in domestic adaptation. Domestic CPU platforms such as Haiguang, Feiteng, and Zhaoxin can operate stably and efficiently, and cover Intel CPU 3-13 generations and desktop CPU 4-14 generations, like a sophisticated computing network, to meet the computing needs of different scenarios. Support for discrete graphics cards from 730 to 4060 allows them to handle complex graphics processing tasks with ease, perfectly adapting to the complex control requirements of automated production lines and becoming key equipment for building digital factories.

The heat of the exhibition site continued to rise. Aiostar's booth was surrounded by crowds of visitors from the manufacturing and automation industries. They almost filled the aisles of the booth. Their faces were full of eagerness for knowledge. Some visitors half-crouched, widened their eyes, and gently brushed their fingers across the interfaces of the industrial computer, carefully checking the layout and type of each interface. From time to time, they took out their notebooks and quickly recorded key information. Some tightly grasped the parameter manual, repeatedly comparing the parameters of different products, frowning slightly, as if weighing which product is more suitable for their production needs. Occasionally, they would whisper a few words with their companions around them and exchange their views. Others held the staff's arms tightly and asked about the configuration information of the product in a rapid pace, from the CPU's computing speed to the graphics processing capabilities of the graphics card, from the expansion interface of the motherboard to the protection level of the tablet computer, every detail was asked thoroughly, for fear of missing any important content. The staff always smiled and patiently answered questions one by one, sometimes pointing to a certain part of the exhibit for detailed explanation, sometimes taking out samples for demonstration. The heated discussions, inquiries and explanations on site were intertwined and echoed over the booth for a long time. What is even more gratifying is that many visitors reached cooperation intentions on the spot after a deep understanding of the products. A purchasing manager from a large automobile manufacturer, after listening to the staff's introduction to the application of 4U industrial computers in automated production lines, immediately made a decision and placed an order for several devices to test. He smiled and said: "The performance of this equipment fully meets the needs of our production line. Let's go back and test the waters first. There will definitely be large orders in the future." Several other manufacturing leaders from remote areas, after learning that the industrial motherboard supports SIM card slots and can be used normally in an environment without a network, signed a large-scale purchase contract with Aiostar on the spot based on their high recognition of the product performance. When the two parties shook hands at the time of signing the contract, their faces were filled with satisfied smiles. The scenes of transactions on the scene became an exceptionally beautiful landscape at the exhibition, attracting many visitors from other booths to stop and watch.

Aiostar's industrial motherboard series is equally rich and varied, and each has its own unique "mission". The 3.5-inch board is compact in size and exquisite in appearance. It is often used in small industrial control equipment, portable testing instruments and other products, and plays an important role in smart home control terminals, small medical monitoring equipment and other fields. It supports the installation of multiple USB ports, display ports and COM ports, which can meet the simple data interaction and display needs between the device and the outside world. At the same time, an M.2 interface can be installed to facilitate storage expansion. The 4-inch board is slightly larger than the 3.5-inch board. It is more common in small automation equipment, smart meters and other products. It is suitable for edge nodes in the industrial Internet of Things and other fields. It supports the installation of network ports and STAT interfaces to facilitate device access to the network and data storage, and is equipped with a SIM card slot, so that it can be used normally when there is no network in mountainous or remote

The 10¡Á10 board has a regular size and is often used in embedded systems, smart terminal devices and other products. It performs well in the fields of intelligent traffic signal control and small environmental monitoring equipment. It supports the installation of multiple USB and COM ports, which is convenient for connecting various sensors and control modules. At the same time, it can be equipped with PCIe interfaces to provide the possibility of expansion functions. The NANO ITX board is small and exquisite, suitable for products with extremely limited space, such as thin clients, smart home central controllers, etc., and is widely used in office automation terminals, small industrial robot control modules and other fields. It supports the installation of display interfaces, network ports and M.2 interfaces to meet the display, network connection and high-speed storage requirements of the device. The design of the SIM card slot also allows it to work normally in remote areas without a network. MINI ATX boards are more common in small servers, industrial control hosts and other products, and are suitable for small and medium-sized industrial automation control systems, data acquisition servers and other fields. It supports the installation of multiple PCIe interfaces, USB interfaces and network ports, which can connect a variety of expansion devices and networks. At the same time, it can be equipped with STAT interfaces to meet the needs of large amounts of data storage. The MINI ITX board is of moderate size and is often used in products such as microcomputers and smart home control centers. It plays a role in digital signage, small monitoring hosts and other fields. It supports the installation of COM ports, display interfaces and M.2 interfaces, which facilitates communication with external devices and display output. It also supports SIM card slots to ensure normal operation in areas without networks. The ATX motherboard is the "giant" among motherboards. It has a large appearance and size and is often used in high-performance industrial computers, servers and other products. It is indispensable in large industrial control centers, data processing servers and other fields. It supports the installation of a variety of interfaces, including multiple USB, network ports, COM ports, display interfaces, and multiple PCIe, STAT and M.2 interfaces. It has strong expansion capabilities and can meet the various connection and expansion requirements of complex industrial systems. The SIM card slot also allows it to work stably in remote areas. These motherboards provide solid hardware support for various industrial equipment with their excellent quality and good compatibility.

Industrial tablet computers also have many highlights. Their screen sizes range from 7 inches to 22 inches, and they can adapt to different operating spaces and usage requirements. Made of high-quality aluminum alloy, they have excellent corrosion resistance. Even in harsh industrial environments full of oil, chemical gases, they can maintain a good appearance and stable performance. Moreover, the dust-free design effectively blocks dust from entering the equipment, avoiding failures caused by dust accumulation, and allowing the equipment to operate normally in dusty factory workshops, mines and other places. In terms of performance, industrial tablet computers support Intel CPUs and domestic CPUs, and support for independent graphics cards 730 - 4060 ensures smooth work. Its adaptability to the working environment and storage environment has withstood rigorous tests. It can still run stably without freezing or crashing in extreme environments such as high and low temperatures and humidity. In on-site operations, staff can quickly enter and query data through it; in data collection scenarios, it can accurately capture various types of production information and become the most reliable "industrial partner" in the hands of operators.

At the exhibition, professionals in the manufacturing and automation industries were deeply attracted by Aiostar's products. Engineers carefully studied the internal structure of industrial computers and the interface configuration of motherboards, and discussed with staff the specific applications in AI robot control and industrial automatic production lines; equipment purchasing decision makers paid attention to the cost-effectiveness and long-term stability of the products, and asked about the adaptation of different motherboards and tablets in various industrial scenarios; scholars showed great interest in the technical innovations of the products and exchanged ideas on the development trends of future industrial equipment. Everyone had in-depth exchanges with Aiostar staff, and every discussion was full of collisions of ideas. Many people expressed a strong intention to cooperate and hoped to apply these high-quality industrial equipment to their own projects. With the help of this exhibition, Aiostar not only fully demonstrated its technical strength and product competitiveness in the field of industrial equipment, but also demonstrated the outstanding style of China's industrial equipment manufacturing to the world. In the wave of digitalization and intelligence, Aiostar's products are like solid cornerstones, providing strong support for the construction of global digital factories, and allowing the world to see the vigorous vitality of China's industrial technology innovation and breakthroughs. I believe that in the future, they will shine in more industrial scenarios and promote the global industrial intelligence process to a new height.